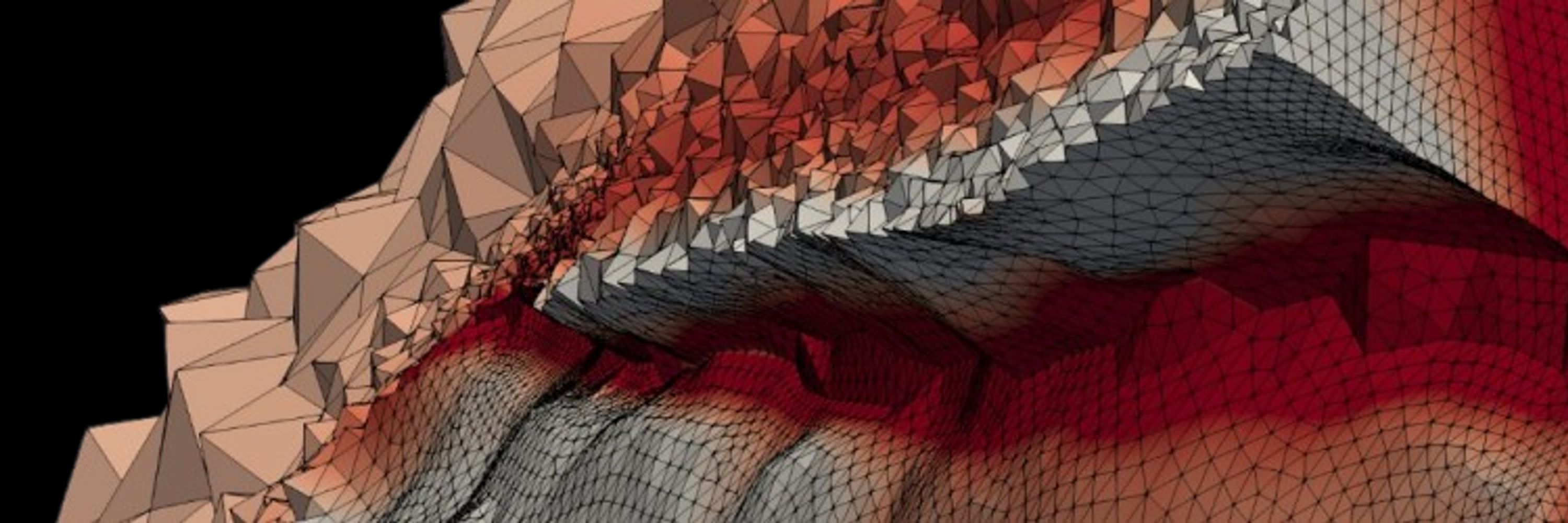

The figure shows a comparison of pellet fragmentation under different loading orientations. Each colour represents distinct fragments formed after primary failure.

The figure shows a comparison of pellet fragmentation under different loading orientations. Each colour represents distinct fragments formed after primary failure.

#FDEM #MaterialModeling #FractureMechanics #Engineering #Geomechanics #Simulation #FEM #DEM #TanukiTechnologies

#FDEM #MaterialModeling #FractureMechanics #Engineering #Geomechanics #Simulation #FEM #DEM #TanukiTechnologies

Using high-speed video recording of mechanical crushing experiments, I was able to compare simulation results with real-world fracture behaviour—proving that FDEM is a powerful tool for modelling complex material failure.

Using high-speed video recording of mechanical crushing experiments, I was able to compare simulation results with real-world fracture behaviour—proving that FDEM is a powerful tool for modelling complex material failure.

Using high-speed video recording of mechanical crushing experiments, I was able to compare simulation results with real-world fracture behaviour—proving that FDEM is a powerful tool for modelling complex material failure.

Using high-speed video recording of mechanical crushing experiments, I was able to compare simulation results with real-world fracture behaviour—proving that FDEM is a powerful tool for modelling complex material failure.

Using high-speed video recording of mechanical crushing experiments, I was able to compare simulation results with real-world fracture behaviour—proving that FDEM is a powerful tool for modelling complex material failure.

Using high-speed video recording of mechanical crushing experiments, I was able to compare simulation results with real-world fracture behaviour—proving that FDEM is a powerful tool for modelling complex material failure.

Using high-speed video recording of mechanical crushing experiments, I was able to compare simulation results with real-world fracture behaviour—proving that FDEM is a powerful tool for modelling complex material failure.

Using high-speed video recording of mechanical crushing experiments, I was able to compare simulation results with real-world fracture behaviour—proving that FDEM is a powerful tool for modelling complex material failure.

The figure below gives an overview of FDEM in action:

(a) Contact interactions and body motion

(b) Stress and deformation calculations

(c) Fracture and fragmentation processes

https://buff.ly/4b6tkhH

The figure below gives an overview of FDEM in action:

(a) Contact interactions and body motion

(b) Stress and deformation calculations

(c) Fracture and fragmentation processes

https://buff.ly/4b6tkhH

FDEM is a great tool for solving complex problems in engineering, geomechanics, and material science.

FDEM is a great tool for solving complex problems in engineering, geomechanics, and material science.

You can read the publication here: https://buff.ly/3WRAd0i

You can read the publication here: https://buff.ly/3WRAd0i

#FDEM #BrazilianDiscTest #FractureMechanics #MaterialModeling #Geomechanics #RockMechanics #NumericalModeling #EngineeringSimulation #ComputationalMechanics #FEM #DEM #TanukiTechnologies

Additionally, you can see two frames from a video recording of a uniaxial compressive test on a cylinder, further highlighting FDEM’s ability to capture fracture mechanics in brittle materials.

Additionally, you can see two frames from a video recording of a uniaxial compressive test on a cylinder, further highlighting FDEM’s ability to capture fracture mechanics in brittle materials.

🔹 (a) The tensile stress field before failure, reaching the tensile strength at the disc’s center.

🔹 (b) Crack propagation from the centre outward.

🔹 (c) The splitting of the disc.

🔹 (a) The tensile stress field before failure, reaching the tensile strength at the disc’s center.

🔹 (b) Crack propagation from the centre outward.

🔹 (c) The splitting of the disc.

#ShapeOptimization #ComputationalMechanics #NumericalSimulations #FEniCS #PhaseField #FEM