Greg Saunier

@gregsaunier.bsky.social

600 followers

310 following

510 posts

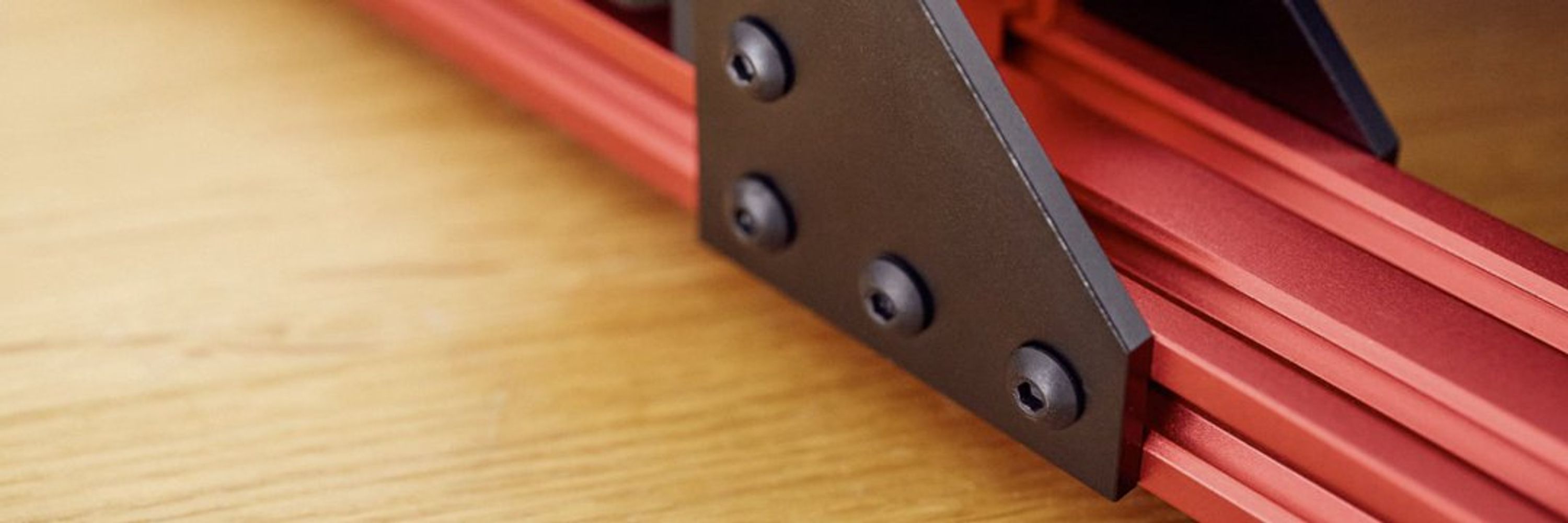

Bear Upgrades designer. I also share informative content on 3D printing and open source.

#3dprinting #opensource #engineering #mechanical

https://ekunn.com

https://github.com/gregsaun

https://patreon.com/gregsaun

https://fosstodon.org/@bear_lab

Posts

Media

Videos

Starter Packs

Reposted by Greg Saunier

Reposted by Greg Saunier

Reposted by Greg Saunier

Reposted by Greg Saunier

Greg Saunier

@gregsaunier.bsky.social

· Aug 28

Greg Saunier

@gregsaunier.bsky.social

· Aug 27

Greg Saunier

@gregsaunier.bsky.social

· Aug 27

Greg Saunier

@gregsaunier.bsky.social

· Aug 22

Greg Saunier

@gregsaunier.bsky.social

· Aug 22

Greg Saunier

@gregsaunier.bsky.social

· Aug 22

Greg Saunier

@gregsaunier.bsky.social

· Aug 22

Reposted by Greg Saunier

Greg Saunier

@gregsaunier.bsky.social

· Aug 22

Greg Saunier

@gregsaunier.bsky.social

· Aug 20

Greg Saunier

@gregsaunier.bsky.social

· Aug 20

Greg Saunier

@gregsaunier.bsky.social

· Aug 19

nixCraft

@cyberciti.biz

· Aug 18

GitHub - pluja/awesome-privacy: Awesome Privacy - A curated list of services and alternatives that respect your privacy because PRIVACY MATTERS.

Awesome Privacy - A curated list of services and alternatives that respect your privacy because PRIVACY MATTERS. - pluja/awesome-privacy

github.com

Greg Saunier

@gregsaunier.bsky.social

· Aug 17

Greg Saunier

@gregsaunier.bsky.social

· Aug 16

Greg Saunier

@gregsaunier.bsky.social

· Aug 16

Greg Saunier

@gregsaunier.bsky.social

· Aug 15

Greg Saunier

@gregsaunier.bsky.social

· Aug 15

Greg Saunier

@gregsaunier.bsky.social

· Aug 15