Guim P.

@guimpt.bsky.social

Passionate about everything related to electronics and robotics.

Electronics freelancer when the sun rises and hobbyist when the sun falls.

Electronics freelancer when the sun rises and hobbyist when the sun falls.

September 22, 2025 at 6:35 PM

That's more like it! The R45 PCB Motor and the R45 PCB Motor Driver are working together to achieve the stiffness and accuracy I was after.

#PCB_Motor

#PCB_Motor

September 18, 2025 at 5:07 PM

That's more like it! The R45 PCB Motor and the R45 PCB Motor Driver are working together to achieve the stiffness and accuracy I was after.

#PCB_Motor

#PCB_Motor

Everything fits and, so far, the first tests with the R45 PCB Motor Driver look very promising!

#PCB_Motor

#PCB_Motor

September 16, 2025 at 3:49 PM

Everything fits and, so far, the first tests with the R45 PCB Motor Driver look very promising!

#PCB_Motor

#PCB_Motor

What else can you ask for than fresh PCBs and some extra goodies in the same box?

Thanks @pcbwayofficial.bsky.social!

Thanks @pcbwayofficial.bsky.social!

September 12, 2025 at 2:13 PM

What else can you ask for than fresh PCBs and some extra goodies in the same box?

Thanks @pcbwayofficial.bsky.social!

Thanks @pcbwayofficial.bsky.social!

Just received another package from @pcbwayofficial.bsky.social!

These PCBs are for the R45 PCB Motor Driver, a custom BLDC driver for the R45 PCB Motor.

Huge thanks to www.pcbway.com for supporting this project!

#PCB_Motor

These PCBs are for the R45 PCB Motor Driver, a custom BLDC driver for the R45 PCB Motor.

Huge thanks to www.pcbway.com for supporting this project!

#PCB_Motor

September 10, 2025 at 4:07 PM

Just received another package from @pcbwayofficial.bsky.social!

These PCBs are for the R45 PCB Motor Driver, a custom BLDC driver for the R45 PCB Motor.

Huge thanks to www.pcbway.com for supporting this project!

#PCB_Motor

These PCBs are for the R45 PCB Motor Driver, a custom BLDC driver for the R45 PCB Motor.

Huge thanks to www.pcbway.com for supporting this project!

#PCB_Motor

Nothing like a blender render to better cope with the wait for the PCBs for the R45 PCB Motor Driver to arrive...

#PCB_Motor

#PCB_Motor

August 20, 2025 at 3:29 PM

Nothing like a blender render to better cope with the wait for the PCBs for the R45 PCB Motor Driver to arrive...

#PCB_Motor

#PCB_Motor

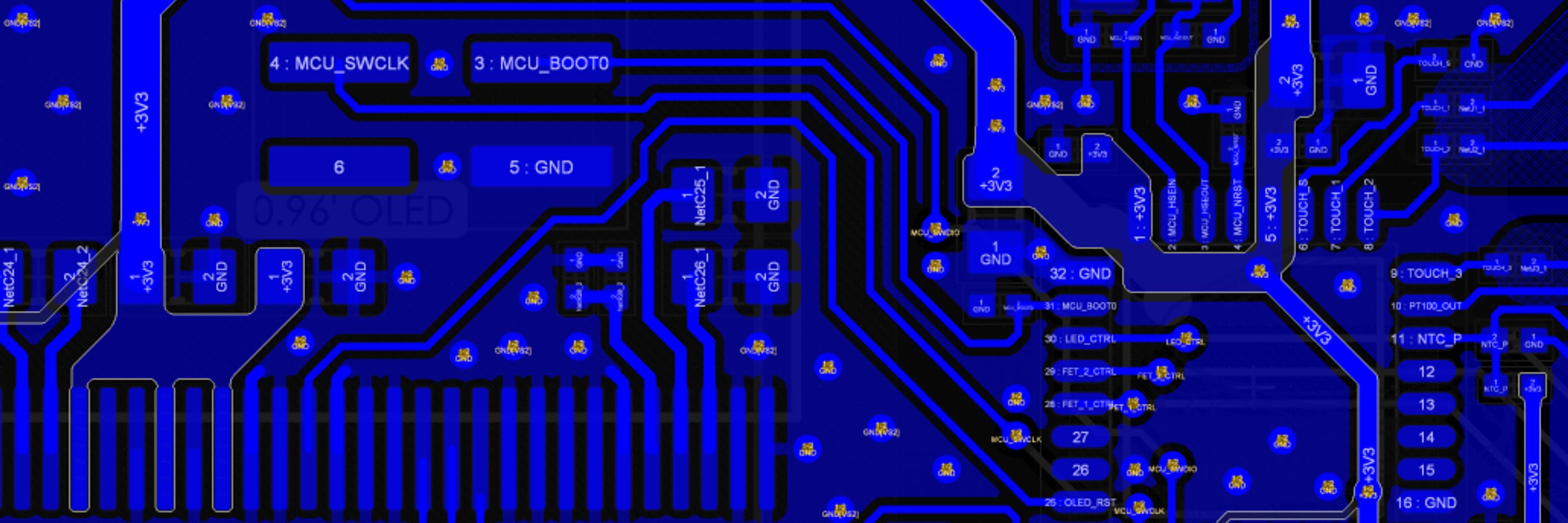

Nothing like a vacation day to make some progress! This is the PCB Motor Driver for the R45 PCBM.

#PCB_Motor

#PCB_Motor

August 12, 2025 at 4:05 PM

Nothing like a vacation day to make some progress! This is the PCB Motor Driver for the R45 PCBM.

#PCB_Motor

#PCB_Motor

August 7, 2025 at 5:41 PM

After some oscilloscope and kitchen scale tests, I can confirm that the Kv of the four R45 motor stack is now 1/4 of the original and torque (Kt) is 4 times the original.

#PCB_Motor

#PCB_Motor

July 14, 2025 at 4:49 PM

After some oscilloscope and kitchen scale tests, I can confirm that the Kv of the four R45 motor stack is now 1/4 of the original and torque (Kt) is 4 times the original.

#PCB_Motor

#PCB_Motor

As expected, the thermal performance of the stacked assembly of R45 PCB Motors is degraded, but not by a lot.

The image shows the results of 2.5A flowing through the Motor.

I wonder if adding thermal pads between PCBs would improve heat spreading and help avoid hotspots.

#PCB_Motor

The image shows the results of 2.5A flowing through the Motor.

I wonder if adding thermal pads between PCBs would improve heat spreading and help avoid hotspots.

#PCB_Motor

July 9, 2025 at 4:54 PM

As expected, the thermal performance of the stacked assembly of R45 PCB Motors is degraded, but not by a lot.

The image shows the results of 2.5A flowing through the Motor.

I wonder if adding thermal pads between PCBs would improve heat spreading and help avoid hotspots.

#PCB_Motor

The image shows the results of 2.5A flowing through the Motor.

I wonder if adding thermal pads between PCBs would improve heat spreading and help avoid hotspots.

#PCB_Motor

Started tests stacking various R45 PCB Motor boards.

These are 4 boards stacked in a series configuration. Will I get close to 4x the torque for the same current? How will the stacked assembly perform thermally?

#PCB_Motor

These are 4 boards stacked in a series configuration. Will I get close to 4x the torque for the same current? How will the stacked assembly perform thermally?

#PCB_Motor

July 7, 2025 at 3:50 PM

Started tests stacking various R45 PCB Motor boards.

These are 4 boards stacked in a series configuration. Will I get close to 4x the torque for the same current? How will the stacked assembly perform thermally?

#PCB_Motor

These are 4 boards stacked in a series configuration. Will I get close to 4x the torque for the same current? How will the stacked assembly perform thermally?

#PCB_Motor

June 30, 2025 at 4:42 PM

Quick phasing plus linearity check of the R45 PCB Motor. The linearity is quite good considering all mechanical parts are 3d printed.

June 26, 2025 at 3:52 PM

Quick phasing plus linearity check of the R45 PCB Motor. The linearity is quite good considering all mechanical parts are 3d printed.

June 23, 2025 at 4:55 PM

June 19, 2025 at 3:42 PM

First spins of the R45 PCB Motor!

Right now it's running in open loop mode (without an encoder).

#PCB_Motor

Right now it's running in open loop mode (without an encoder).

#PCB_Motor

June 16, 2025 at 5:40 PM

First spins of the R45 PCB Motor!

Right now it's running in open loop mode (without an encoder).

#PCB_Motor

Right now it's running in open loop mode (without an encoder).

#PCB_Motor

All the magnets have been glued.

Inspecting the fields with a magnetic viewing film reveals that the Halbach configuration behaves as predicted by the simulations.

#PCB_Motor

Inspecting the fields with a magnetic viewing film reveals that the Halbach configuration behaves as predicted by the simulations.

#PCB_Motor

June 13, 2025 at 4:32 PM

All the magnets have been glued.

Inspecting the fields with a magnetic viewing film reveals that the Halbach configuration behaves as predicted by the simulations.

#PCB_Motor

Inspecting the fields with a magnetic viewing film reveals that the Halbach configuration behaves as predicted by the simulations.

#PCB_Motor

Placing the magnets in a Hallbach configuration is trickier than I initially expected, the magnets do not want to stay in place. Time for CA glue!

#PCB_Motor

#PCB_Motor

June 12, 2025 at 5:32 PM

Placing the magnets in a Hallbach configuration is trickier than I initially expected, the magnets do not want to stay in place. Time for CA glue!

#PCB_Motor

#PCB_Motor

Today I received the magnets for the R45 PCB Motor.

The magnets have been marked and now it's time to place them one by one in a Hallbach configuration.

#PCB_Motor

The magnets have been marked and now it's time to place them one by one in a Hallbach configuration.

#PCB_Motor

June 11, 2025 at 5:20 PM

Today I received the magnets for the R45 PCB Motor.

The magnets have been marked and now it's time to place them one by one in a Hallbach configuration.

#PCB_Motor

The magnets have been marked and now it's time to place them one by one in a Hallbach configuration.

#PCB_Motor

In order to achieve high torques in a PCB Motor the amount of copper plays a major role.

The following spreadsheet has been used in order to evaluate what some of the best available options are.

PCBWay's 10L 6oz stackup looks very promising but it's expensive for low quantities...

#PCB_Motor

The following spreadsheet has been used in order to evaluate what some of the best available options are.

PCBWay's 10L 6oz stackup looks very promising but it's expensive for low quantities...

#PCB_Motor

June 6, 2025 at 4:53 PM

In order to achieve high torques in a PCB Motor the amount of copper plays a major role.

The following spreadsheet has been used in order to evaluate what some of the best available options are.

PCBWay's 10L 6oz stackup looks very promising but it's expensive for low quantities...

#PCB_Motor

The following spreadsheet has been used in order to evaluate what some of the best available options are.

PCBWay's 10L 6oz stackup looks very promising but it's expensive for low quantities...

#PCB_Motor

The R45 PCB Motor uses a Halbach magnet configuration, which gives it two key advantages:

1. It concentrates the magnetic fields to one side, like having a back iron.

2. It produces a more uniform field even with rectangular magnets instead of arcs (cheaper).

#PCB_Motor

1. It concentrates the magnetic fields to one side, like having a back iron.

2. It produces a more uniform field even with rectangular magnets instead of arcs (cheaper).

#PCB_Motor

June 3, 2025 at 5:48 PM

The R45 PCB Motor uses a Halbach magnet configuration, which gives it two key advantages:

1. It concentrates the magnetic fields to one side, like having a back iron.

2. It produces a more uniform field even with rectangular magnets instead of arcs (cheaper).

#PCB_Motor

1. It concentrates the magnetic fields to one side, like having a back iron.

2. It produces a more uniform field even with rectangular magnets instead of arcs (cheaper).

#PCB_Motor

New package from @pcbwayofficial.bsky.social !

These PCBs are for the R45 PCBM, an evolution of the Comb PCB motor with higher torque capabilities.

The PCBs are 0.6mm & 4 layers. One of the things I want to test is to stack them.

Thank you www.pcbway.com for sponsoring this project!

#PCB_Motor

These PCBs are for the R45 PCBM, an evolution of the Comb PCB motor with higher torque capabilities.

The PCBs are 0.6mm & 4 layers. One of the things I want to test is to stack them.

Thank you www.pcbway.com for sponsoring this project!

#PCB_Motor

May 30, 2025 at 5:04 PM

New package from @pcbwayofficial.bsky.social !

These PCBs are for the R45 PCBM, an evolution of the Comb PCB motor with higher torque capabilities.

The PCBs are 0.6mm & 4 layers. One of the things I want to test is to stack them.

Thank you www.pcbway.com for sponsoring this project!

#PCB_Motor

These PCBs are for the R45 PCBM, an evolution of the Comb PCB motor with higher torque capabilities.

The PCBs are 0.6mm & 4 layers. One of the things I want to test is to stack them.

Thank you www.pcbway.com for sponsoring this project!

#PCB_Motor

Performed some thermal testing on the Comb PCB Motor.

As a result, its rated current has been found to be 1.6 A.

#PCB_Motor

As a result, its rated current has been found to be 1.6 A.

#PCB_Motor

May 28, 2025 at 4:27 PM

Performed some thermal testing on the Comb PCB Motor.

As a result, its rated current has been found to be 1.6 A.

#PCB_Motor

As a result, its rated current has been found to be 1.6 A.

#PCB_Motor