youtu.be/LLr1J-xyRG4

Results are very surprising! 😎

Small sneak peek of PLA results!

#3dprinting #3dprint #3dprinter #filament

youtu.be/LLr1J-xyRG4

Results are very surprising! 😎

Small sneak peek of PLA results!

#3dprinting #3dprint #3dprinter #filament

youtu.be/LLr1J-xyRG4

Results are very surprising! 😎

Small sneak peek of PLA results!

#3dprinting #3dprint #3dprinter #filament

Also, my brain is cooked after this... week... of testing...

Also, my brain is cooked after this... week... of testing...

Printed on my Voron 2.4 with a 0.5mm nozzle using Sunlu PA12-CF, with outer walls printed first.

Used 5 walls and 50% infill, so some warping was hard to avoid. Good thing that didn’t impact the design.

Printed on my Voron 2.4 with a 0.5mm nozzle using Sunlu PA12-CF, with outer walls printed first.

Used 5 walls and 50% infill, so some warping was hard to avoid. Good thing that didn’t impact the design.

It was CNC machined from aluminum by @pcbwayofficial.bsky.social 👍

It was CNC machined from aluminum by @pcbwayofficial.bsky.social 👍

youtu.be/bkw03qd5JTM

The size of this Thing is INSANE!!! 🙃

But is it good or just another big 3D printer plagued with many issues? Watch the video!

youtu.be/bkw03qd5JTM

The size of this Thing is INSANE!!! 🙃

But is it good or just another big 3D printer plagued with many issues? Watch the video!

I kept both parts for 5min in the Sunlu E2 Dryer at 90 °C.

The PETG part becomes like TPU, and the ABS part is still perfectly stiff with no deformation.

I kept both parts for 5min in the Sunlu E2 Dryer at 90 °C.

The PETG part becomes like TPU, and the ABS part is still perfectly stiff with no deformation.

Well, it is a piece of cake compared to reassembling the ballscrew... 🥲🥲🥲

Well, it is a piece of cake compared to reassembling the ballscrew... 🥲🥲🥲

So... This was ~0.7kg print... and it wasn't even that big. 3kg spools are the norm here. But the variety of them and air-tight dry boxes are so limited. 🥲

So... This was ~0.7kg print... and it wasn't even that big. 3kg spools are the norm here. But the variety of them and air-tight dry boxes are so limited. 🥲

35mm length meltzone (the longest from all my tested hotends) and standard V6 nozzles.

Do you think it could outperform any of the current TOP 3 hotends? 🧐

35mm length meltzone (the longest from all my tested hotends) and standard V6 nozzles.

Do you think it could outperform any of the current TOP 3 hotends? 🧐

I could probably squeeze to 0.15mm, but that would be just a waste of time with no real benefit. 🤓

I could probably squeeze to 0.15mm, but that would be just a waste of time with no real benefit. 🤓

Testing these hotends by layer adhesion and extrusion force:

- Slice Engineer Mako

- MicroSwiss FlowTech

- Phaetus Conch M6

- 3Dc Starlex DHB

- E3D HF ObXidian

Thanks to all the companies that participated in this testing!

Testing these hotends by layer adhesion and extrusion force:

- Slice Engineer Mako

- MicroSwiss FlowTech

- Phaetus Conch M6

- 3Dc Starlex DHB

- E3D HF ObXidian

Thanks to all the companies that participated in this testing!

Even the photos don't relay the actual size... It is ridiculous!

This thing is never leaving this place, even if someone tried to steal it. 😂

Even the photos don't relay the actual size... It is ridiculous!

This thing is never leaving this place, even if someone tried to steal it. 😂

Same length melt zone. Regular vs CHT design. I don't know how this E3D hotend still manages to keep amazing me... 🤯

(lower=better)

#3dprint #3dprinter #3dprinting

Same length melt zone. Regular vs CHT design. I don't know how this E3D hotend still manages to keep amazing me... 🤯

(lower=better)

#3dprint #3dprinter #3dprinting

I have some nice and interesting hotends to test:

SliceEngineer Mako™

MicroSwissLLC FlowTech™

phaetus3D Conch V6

Swiss3Dc Starlex DHB

🙃

I have some nice and interesting hotends to test:

SliceEngineer Mako™

MicroSwissLLC FlowTech™

phaetus3D Conch V6

Swiss3Dc Starlex DHB

🙃

It should be easy to implement, as it is the opposite of the print speed, no? I would love this for filaments like ABS, PA, for the best strength and the look.

It should be easy to implement, as it is the opposite of the print speed, no? I would love this for filaments like ABS, PA, for the best strength and the look.

You can pack so much more desiccant into the AMS unit if you also put desiccant into the middle of the spools.

I used this model (but there are a lot of them): makerworld.com/en/models/12...

You can pack so much more desiccant into the AMS unit if you also put desiccant into the middle of the spools.

I used this model (but there are a lot of them): makerworld.com/en/models/12...

In this video, I explored what happens if you print at a narrower extrusion width than the nozzle size.

In this video, I explored what happens if you print at a narrower extrusion width than the nozzle size.

But I don't think it will replace the P1/X1 for more casual makers.

Our most advanced multifunctional manufacturing hub yet.

Ready to take personal manufacturing to the next level?

Order now.

👀 www.youtube.com/watch?v=idOY...

#BambuH2D #RethinkPersonalManufacturing

But I don't think it will replace the P1/X1 for more casual makers.

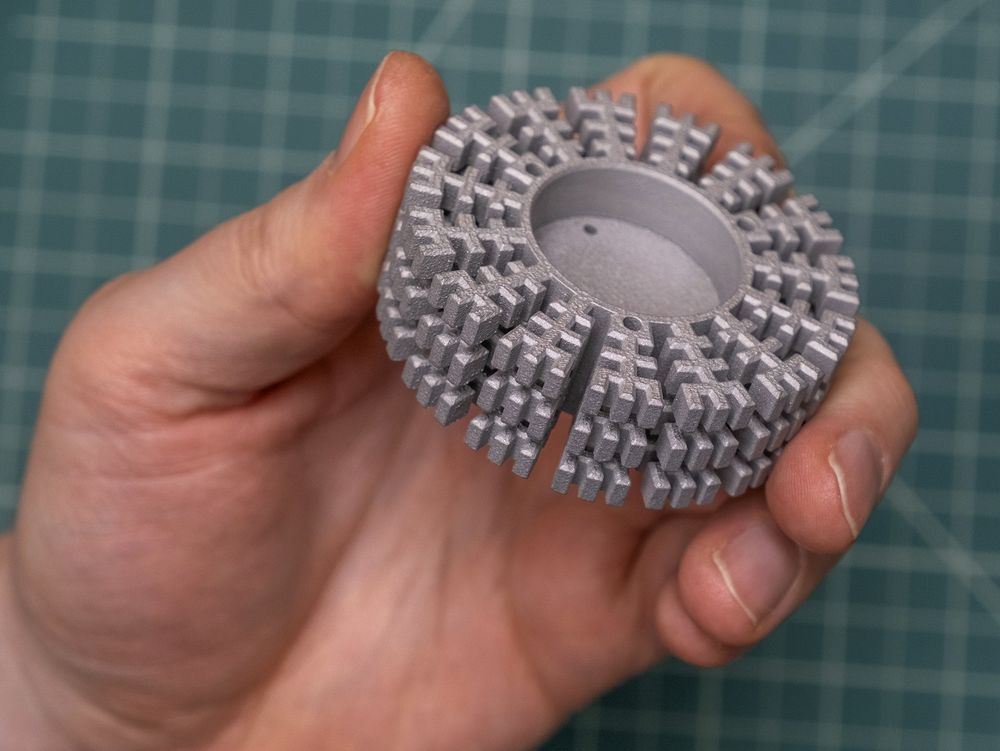

3D printed from aluminum by @pcbwayofficial.bsky.social

I still need to sand the mounting surface and tap the threads, but hopefully, the huge amount of surface area will help dissipate heat better than any regular heatsink of this size. 😊

3D printed from aluminum by @pcbwayofficial.bsky.social

I still need to sand the mounting surface and tap the threads, but hopefully, the huge amount of surface area will help dissipate heat better than any regular heatsink of this size. 😊