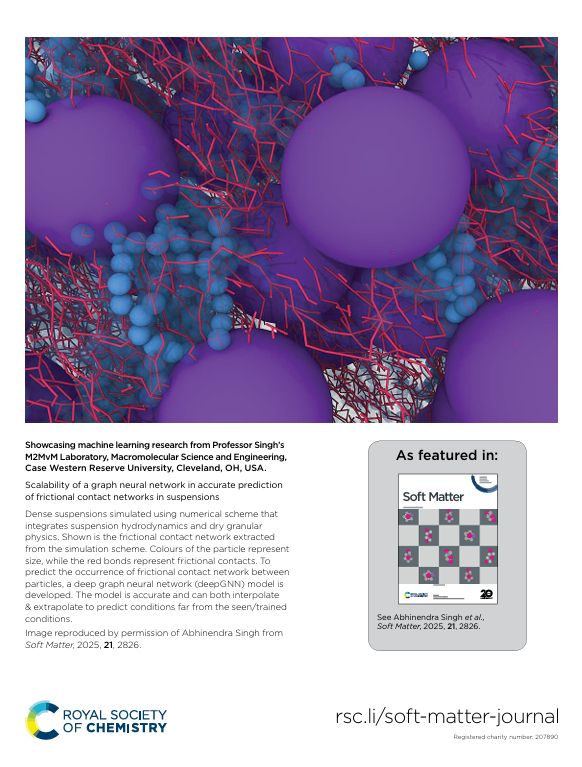

https://web.uri.edu/soft-matter-lab/

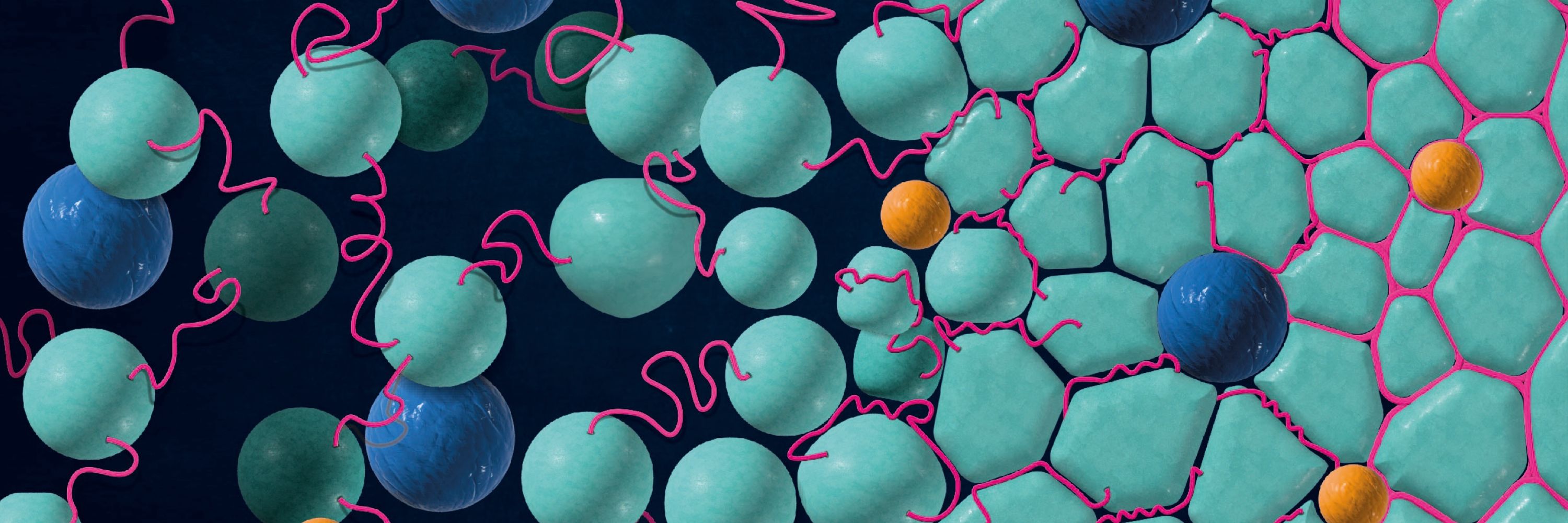

1. The RATE of aggregation is a more precise metric to define phase boundaries than size, and

2. PGNPs aggregate like globular polymers rather than colloids.

We seek a dynamic and personable individual with postdoctoral experience in soft matter and statistical physics, to join our close-knit team of editors running the world’s leading physics journal. aps.applicantstack.com/x/detail/a27...

We seek a dynamic and personable individual with postdoctoral experience in soft matter and statistical physics, to join our close-knit team of editors running the world’s leading physics journal. aps.applicantstack.com/x/detail/a27...

Background in ME, Physics, ChemE, Civil (or related), interest in fluid mechanics/soft matter, and hands-on lab work are key.

Please help spread the word!

Background in ME, Physics, ChemE, Civil (or related), interest in fluid mechanics/soft matter, and hands-on lab work are key.

Please help spread the word!

1. The RATE of aggregation is a more precise metric to define phase boundaries than size, and

2. PGNPs aggregate like globular polymers rather than colloids.

1. The RATE of aggregation is a more precise metric to define phase boundaries than size, and

2. PGNPs aggregate like globular polymers rather than colloids.

I’m going to be discussing our work on biomaterials and soft matter physics.

I’m going to be discussing our work on biomaterials and soft matter physics.

She has joined us from the University of Zaragoza through our partnership in the IAESTE program and is working on building thermally responsive hydrogels from cellulose.

web.uri.edu/engineering/...

She has joined us from the University of Zaragoza through our partnership in the IAESTE program and is working on building thermally responsive hydrogels from cellulose.

web.uri.edu/engineering/...

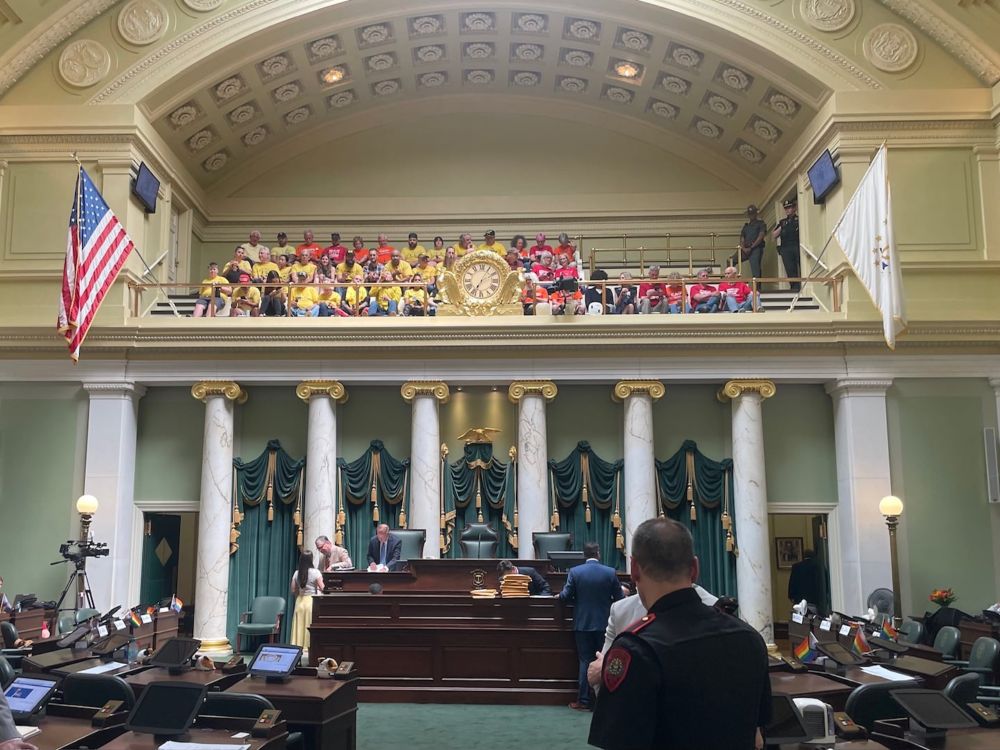

Casualties of Trump’s War on Higher Ed one.npr.org/i/nx-s1-5545...

Casualties of Trump’s War on Higher Ed one.npr.org/i/nx-s1-5545...

Thanks @rhodeislandcurrent.com for the follow up coverage and focus on the students bearing the brunt of these decisions.

Thanks @rhodeislandcurrent.com for the follow up coverage and focus on the students bearing the brunt of these decisions.

Sponsored by USDOT PHMSA, this paper finds that natural gas does not significantly modify the polymer mechanics, making polymer liners a safe and effective option for natural gas pipelines.

Sponsored by USDOT PHMSA, this paper finds that natural gas does not significantly modify the polymer mechanics, making polymer liners a safe and effective option for natural gas pipelines.

The hiring is on a rapid timeline so please apply ASAP. More information in link below. I am also happy to answer any questions!

The hiring is on a rapid timeline so please apply ASAP. More information in link below. I am also happy to answer any questions!

McKee wanting it both ways. Cutting funds but blaming the agency for needing to cut service.

www.bostonglobe.com/2025/08/07/m...

McKee wanting it both ways. Cutting funds but blaming the agency for needing to cut service.

She has been an incredibly productive student in her time in our group working on developing polymer-based anodes for microbial fuel cells, and we are so proud of her current and future success!

She has been an incredibly productive student in her time in our group working on developing polymer-based anodes for microbial fuel cells, and we are so proud of her current and future success!

RI needs to be investing in public transportation not cutting this service.

✅End high-interest rates for payday loans

✅"Freedom to Read" censorship bill

✅Anti-bid-rigging law

❌Budget amendment to avoid RIPTA cuts

❌Sex abuse lawsuit bill

❌Bottle bill

❌CRMC a state agency

www.bostonglobe.com/2025/06/20/m...

RI needs to be investing in public transportation not cutting this service.

#ChemSky #OA